Importance of adhesive coverage rates

Published: 23 February 2022

Updated: 04 March 2022

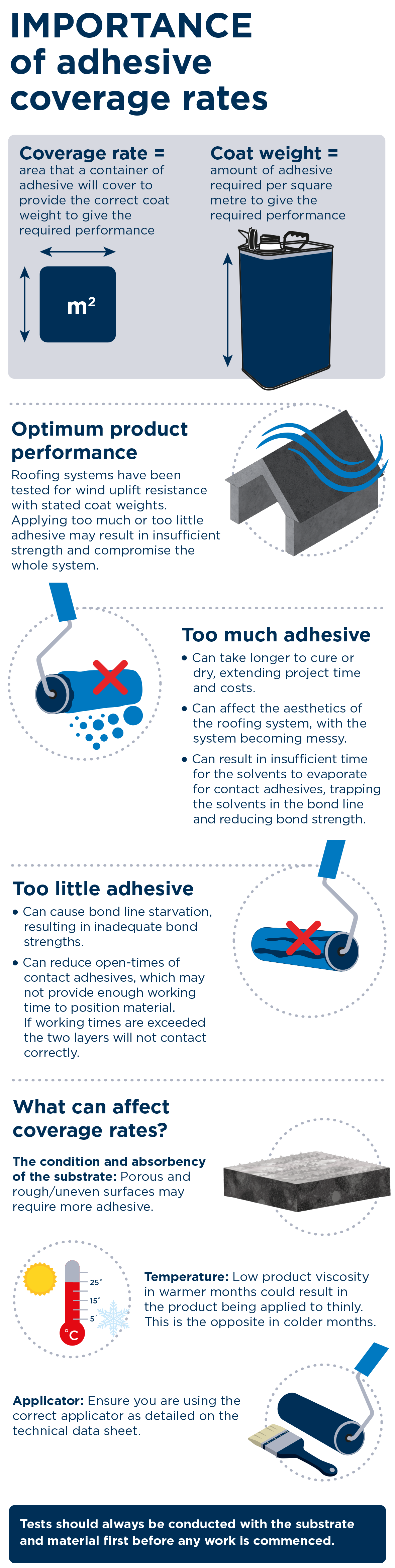

Adhesive coverage rates are provided to ensure optimum product performance. Applying too much or too little adhesive may affect performance and can compromise the whole roofing system. Here Darrell Tibbins, Director of Technical, explains more.

Coverage rates/coat weights are provided for specific reasons.

- Coverage rate = the area that a container of adhesive will cover to provide the correct coat weight to give the required performance

- Coat weight = the amount of adhesive required per square metre to give the required performance

Roofing systems have been tested for wind uplift resistance with the stated coat weights. Applying too much or too little could result in insufficient strength to meet wind uplift and bond strength requirements. It could also diminish the aesthetics of the roof and increase project time and costs.

You should always apply the specified coat-weight/coverage-rate evenly and ensure the correct working time is followed. This will allow for full bonding strength of the membrane/AVCL or insulation board to the substrate.

Image showing too little, right amount, and too much of Apollo Sray-Applied Primer applied to a substrate.

Image showing too little, right amount, and too much of Apollo Sray-Applied Primer applied to a substrate.

Below we explain potential consequences of applying too much or too little adhesive:

Consequences of applying too much adhesive

Applying too much product could result in the adhesive taking longer to cure or dry, extending project time and costs. With cost concerns a key issue amongst contractors, applying too much adhesive is also wasteful, further increasing project costs.

With solvent-based contact adhesives, once applied, the solvents evaporate leaving a solid behind. The adhesive layer must be given time to allow the solvents to evaporate to prevent entrapment in the bond line. Applying too much adhesive may mean there is not enough time for the solvents to evaporate, trapping the solvents in the bond line. This will reduce bond strength and can result in blisters or bubbles forming in the applied membranes/AVCL.

If other elements of the system have been fixed together and the adhesive hasn’t fully cured or dried, the whole roofing system will be compromised.

Too much adhesive can also affect the aesthetics of the roofing system. The system can become messy, with drips and spillages, or it could result in the membrane slipping. With MCPU insulation adhesives, too much adhesive may result in excess foaming the adhesive and result in uneven insulation boards.

Consequences of applying too little adhesive

Applying too little adhesive may cause bond line starvation, resulting in inadequate bond strengths. There may not be enough adhesive present to reach the full bond, meaning the roofing system won’t give the desired performance.

Applying too little adhesive can also reduce the open-times of solvent-based contact adhesives. You may not give yourself enough working time to position your material as it may start to dry too quickly. If working times are exceeded the two layers will not contact correctly resulting in lower bond strengths.

Factors that can affect coverage rates

There are other factors that can determine the coverage rate that needs to be applied. Tests should always be conducted with the substrate and material first before any work is commenced.

Coverage rates can depend on the condition and absorbency of the substrate. A porous surface will require more adhesive as the adhesive soaks into surface. Rough or uneven surfaces may also require extra adhesive.

You should ensure you are using the correct applicator, as detailed on the technical data sheet. Different amounts of adhesive maybe needed depending on the type of notch trowel used or the type of pile on the roller.

Temperature can also affect how much adhesive should be applied. Low product viscosity in warmer summer months could result in the product being applied to thinly, applying less product than is required. This is the opposite in colder winter months, where the high viscosity may make the product difficult to apply, and excessive adhesive may be applied.

Are spray-applied canister products the future?

Canister products can help minimise cost and waste with their controlled coverage rates. It’s easier to apply too much adhesive with a tin-applied product. The pressurised canister system helps to reduce cost, waste and time onsite. It takes the guess work out of adhesive application and makes it easier to apply the right coverage rate, for precise and even application.

For more information, please contact Apollo Roofing’s Technical department.

The below infographic summarises the key points:

You may also be interested in

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.