The importance of a primer for liquid applied membrane roofing projects

Published: 09 September 2022

Updated: 09 September 2022

Here we explain the importance of a primer and review of some of the primers that may be required for PU liquid applied membranes.

This article was featured in Roofing Today 2022 Liquid Waterproofing Supplement

Liquid applied membranes offer durability, reliability and consistency. Suitable for overlay, the systems are ideal for repair or refurbishment projects. They help to extend the life of the roof, without the cost of replacement. They are also a great choice for new build projects because systems can offer long guarantees – but this is dependent on the correct preparation and application.

Primers can help prepare surfaces to improve the adhesion of the liquid applied membrane. However, often the wrong primer, or no primer at all, is used despite their importance. The specified primer has usually been included as part of the system warranty because they have been tested to a high standard. Here Darrell Tibbins, Director of Technical at Apollo Roofing, explains more.

The importance of a primer

The importance of a primer is often overlooked when it comes to liquid waterproofing projects, despite being integral to the adhesion of the waterproofing system – it is what bonds the first layer to the substrate. Using the appropriate primer is vital to maximise the longevity of the roof and to comply with tested data, e.g. BBA Agrément Certification.

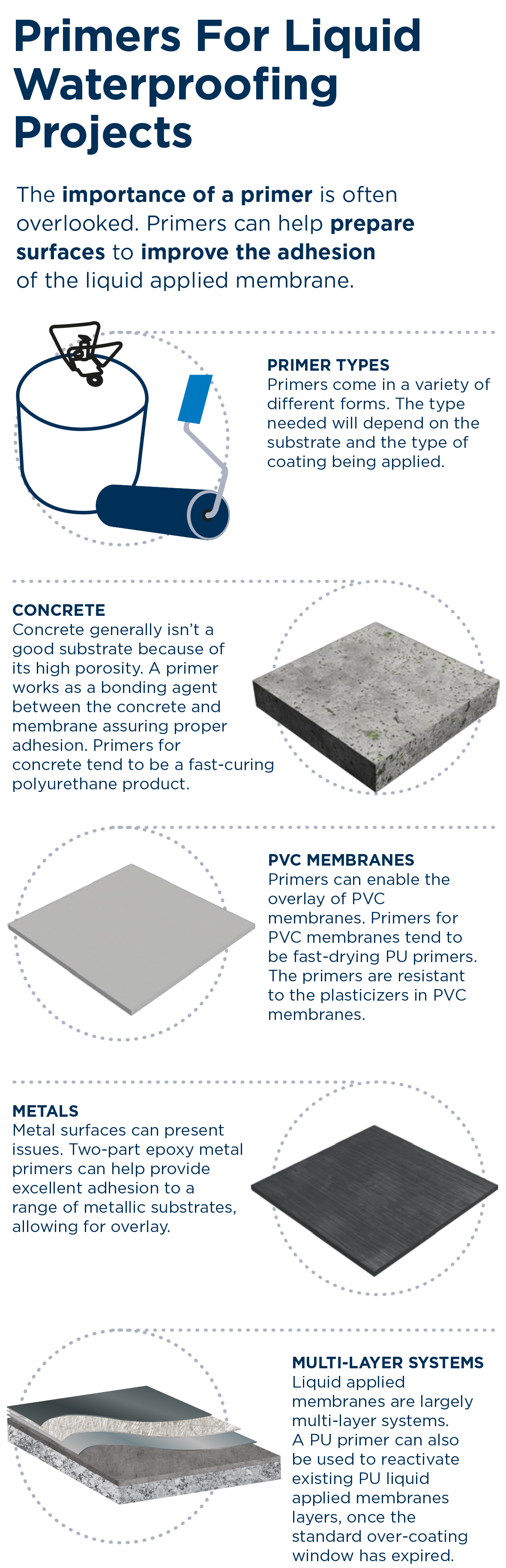

When laying liquid applied membranes, different substrates and applications will present different complexities; however, primers can be used to seal a surface and help adhesion. Primers come in a variety of different forms. They are often substrate specific. The type needed will depend on the substrate and the type of coating being applied. Installing an incorrect primer could lead to system failure in the future.

Primers are also often included as part of the system warranty because they have been tested to a high standard, protecting the longevity of the roof. Therefore, not using the tested primer risks the warranty being invalid, as well as giving unknown performance.

Primer Types

A review of some of the primers that may be required for PU liquid applied membranes is below.

► Concrete, without the use of a primer, isn’t generally a good substrate for holding liquid applied membranes because of its high porosity. A primer works as a bonding agent between the concrete and membrane, assuring proper adhesion to both surfaces and a long-lasting bond. Primers for concrete tend to be a fast-curing polyurethane product.

► A primer can also help enable the overlay of PVC membranes, which eliminates the time and cost of removing the existing roof membrane. Primers for PVC membranes tend to be fast-drying PU primers developed for improving the adhesion properties between PVC-based membranes and liquid applied membranes. PVC primers are resistant to the plasticizers in PVC membranes, which promotes successful overlay and lasting adhesion between the two membranes.

► Metal surfaces can present issues when trying to apply liquid applied membranes. Two-part epoxy metal primers can help provide excellent adhesion to a range of metallic substrates, allowing for overlay. They are ideal for roofing projects where interface details are complex, or substrate adhesion is impaired, e.g. due to poor condition/rust, removing the need for mechanical preparation of the surface.

► Liquid applied membranes are largely multi-layer systems, consisting of a base-coat, an embedded glass fibre mat layer to reinforce the coating, and one or more top-coat layers. A PU primer can also be used to reactivate existing PU liquid applied membranes layers, once the standard over-coating window has expired. This promotes longevity of the roof; it enables the repair of roof damage or for further coats to be applied on multi-layer systems.

Using the appropriate primer is key, especially when part of a system warranty. It reduces the potential for future problems and helps to ensure excellent performance of the waterproofing system.

View our range of liquid applied membrane primers here.

Contact us for more information.

Our infographic below summarises the key points:

You may also be interested in

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.