Bonding Thermal Insulation

Published: 20 January 2020

Updated: 03 August 2023

When it comes to bonding thermal insulation, using the right product for the right job is key. Here we offer advice for getting the best results.

It may be just one of several elements of a roofing system, but thermal insulation represents a significant proportion of the overall system cost. Ensuring that the correct product is used in the correct way will ensure the longevity of the roof and reduce the need for costly repairs in the future. Here we offer advice for getting the best results.

Thermal Insulation Types for Roofs

Flat roof insulation can be one of the main ways to improve thermal performance, reduce heat loss and increase a building’s energy efficiency. There are a variety of insulation types available on the market, each having their own benefits.

The common thermal insulation types used in flat roofing systems include EPS, XPS, PIR boards (including tissue and foil-faced), mineral wool and Foamglas. Some adhesives are more suitable for particular insulation types.

Insulation Bonding options

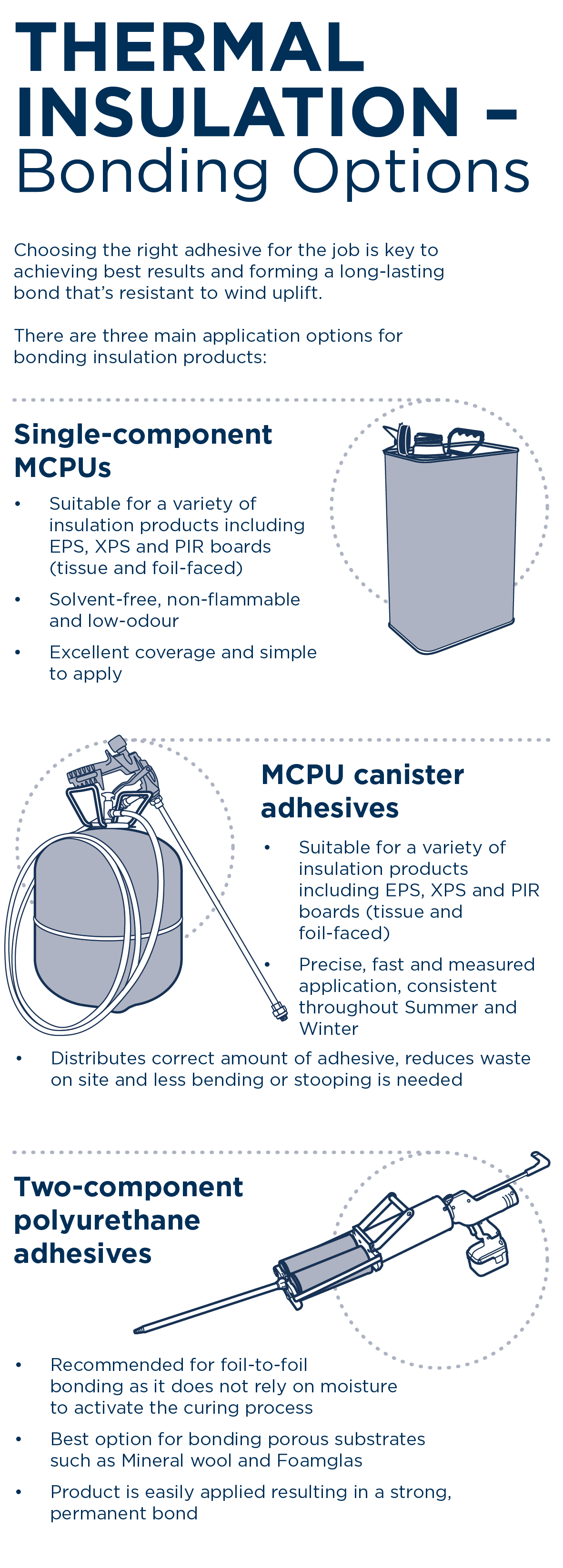

Choosing the right adhesive for the job is key to achieving best results and forming a long-lasting bond that’s resistant to wind uplift.

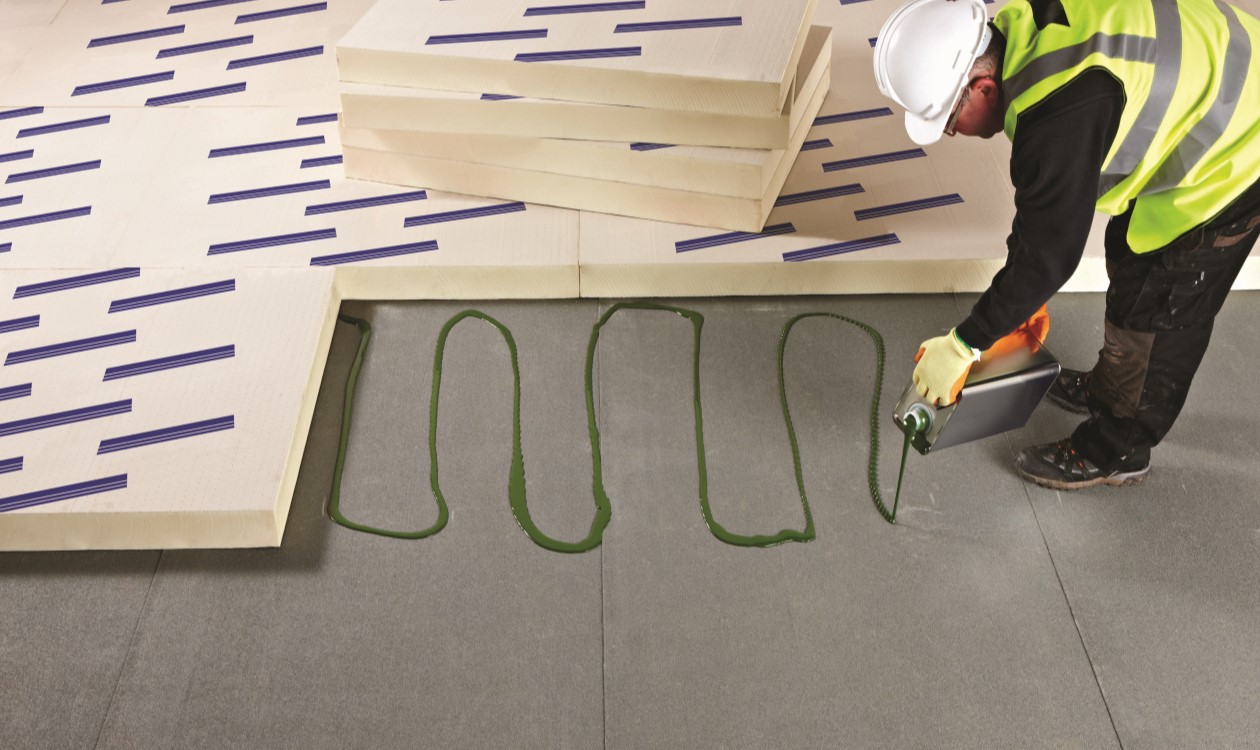

There are three main application options for bonding insulation products; single-component one-way stick moisture-curing polyurethanes (MCPUs) from a tin, MCPUs sprayed from a pressurised spray canister and two-component polyurethane adhesives applied via a dispensing gun.

Single-component MCPU adhesives

Single-component MCPU adhesives are suitable for a variety of insulation products including EPS, XPS and PIR boards, including tissue and foil-faced (to a porous surface). Solvent-free versions also enable contractors to meet green credentials too, being non-flammable and low-odour. These types of adhesives offer excellent coverage and are simple to apply.

MCPU canister adhesives

An alternative application method for MCPU adhesives is spraying from a pressurised canister, instead of simply pouring from a tin. The benefits include; precise, fast and measured application which is consistent throughout the summer and winter months. The canister distributes the correct amount of adhesive, reduces waste on site and it’s a much easier job for the contractor as less bending or stooping is needed.

Once empty, and following the correct de-pressurising procedure, the empty canisters are classed as scrap metal for recycling which offers green credentials. Find out more about canister disposal here.

Two-component polyurethane adhesives

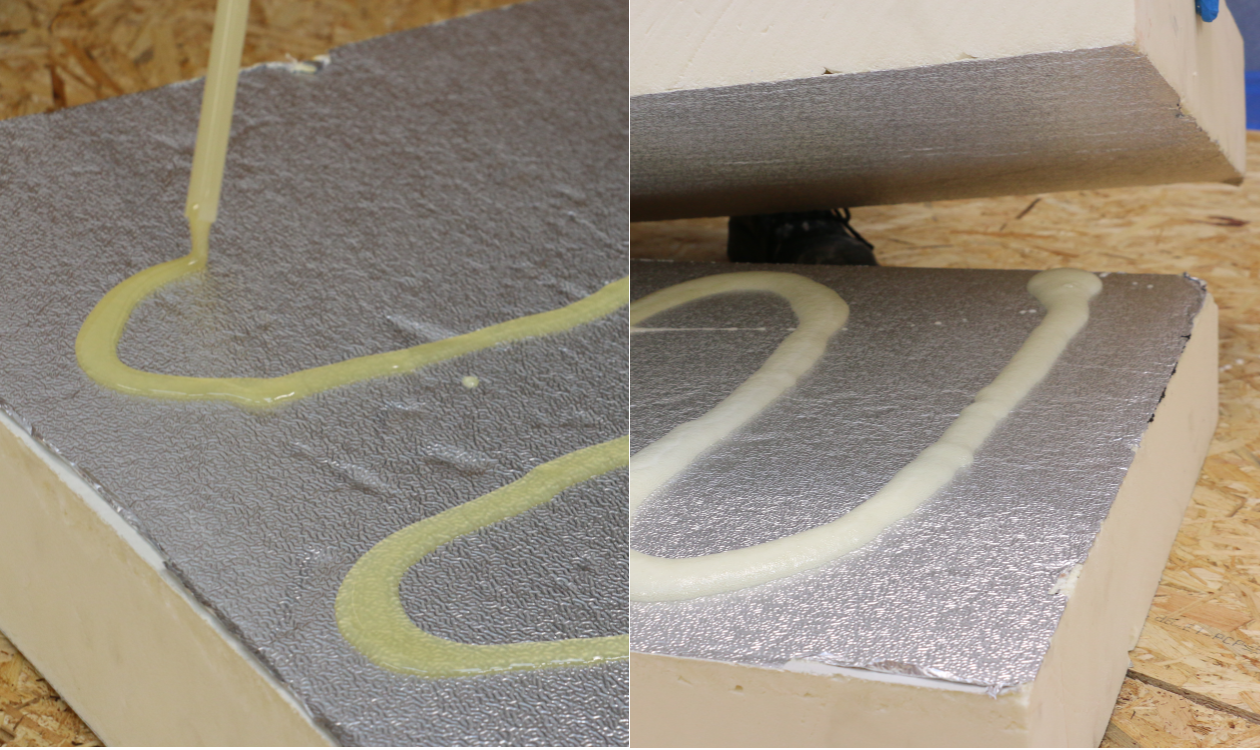

These are best for foil-to-foil bonding. To achieve greater thermal values, it may be required to bond insulation material to itself, and, in the case of foil-to-foil boards, two-component adhesives are recommended to be used to ensure full curing of the adhesive.

Two-component adhesives do not rely on moisture to activate the curing process, and the product is easily applied resulting in a strong, permanent bond.

Two-component adhesives are also the best option for bonding porous substrates such as mineral wool and Foamglas as they benefit from the high foaming structure of these adhesives.

Dos and Don’ts:

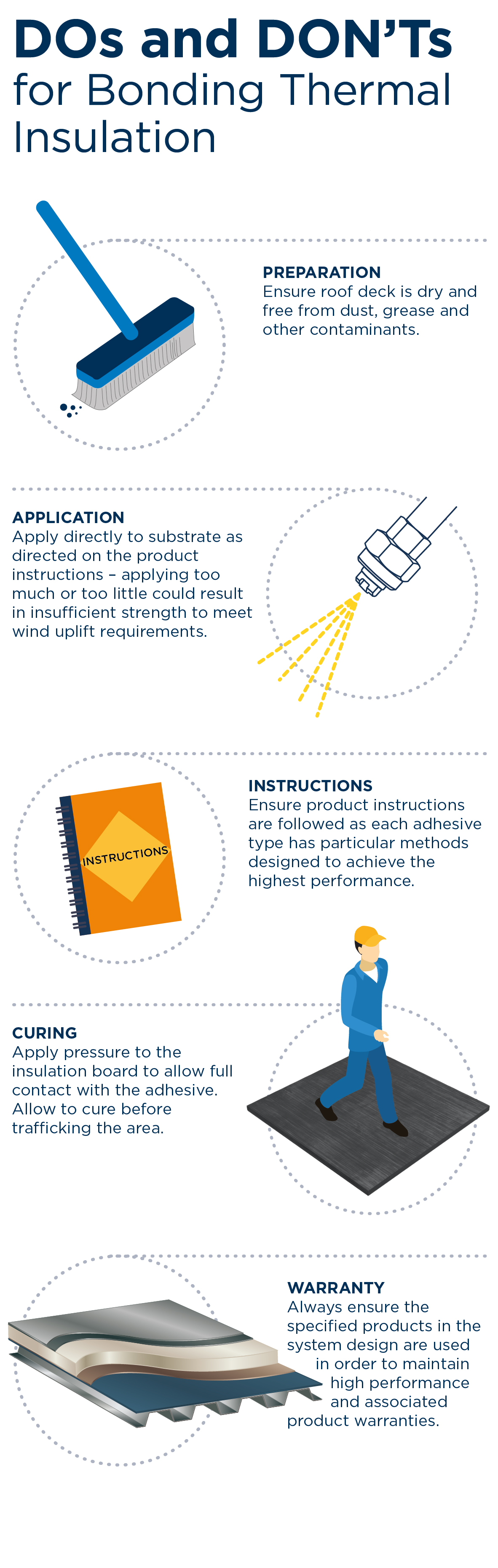

- Ensure roof deck is dry and free from dust, grease and other contaminants – failure to do so will result in delamination/peeling or poor bond strength.

- Apply directly to the substrate as directed on the product packaging – applying too much or too little could result in insufficient strength to meet wind uplift requirements.

- Ensure the product instructions are followed when applying the insulation boards as each adhesive type has particular methods designed to achieve the highest performance.

- Apply pressure to the insulation board to allow full contact with the adhesive

- Allow to cure before trafficking the area.

- Always ensure the specified products in the system design are used in order to maintain high performance and associated product warranties.

Find out more about our range of insulation adhesives here, or contact us to speak with our one of dedicated Sales team.

Our infographics summarise the key points below:

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.